A kneeling chair is a type of chair designed to promote proper posture and reduce discomfort associated with sitting for prolonged periods of time. Unlike traditional chairs that have a horizontal seat, a kneeling chair has a sloping seat and a knee rest that allows the user to sit in a kneeling position. This position […]

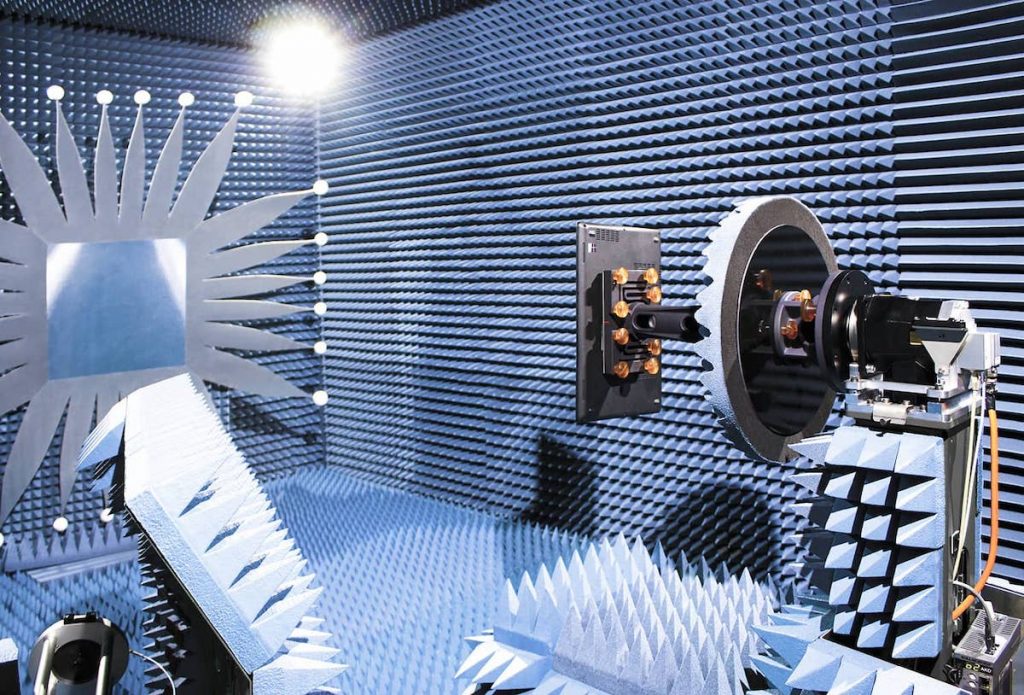

The fifth generation of cellular mobile networks, 5G, is the next big thing in wireless connectivity. But what exactly is 5G? What are its key features and benefits? In this article, we’ll take a look at 5G mmWave technology and explain everything you need to know about it. So, what is 5G mmWave technology? Put […]

Technology is really important for our life. We use technology to communicate with others, but this can actually make us feel more alone. We rely on technology to stay connected with people we care about, but technology can also isolate us from the real world. A case study from the University of Michigan found that […]

Although Amazon remains the singular titan of online shopping, Canadian company Shopify has carved out space as an e-Commerce force to be reckoned with. The company had a banner year in 2021, with holiday sales in particular breaking records; according to CNBC, Shopify’s Cyber Monday transactions alone brought in over $5 billion. Just a few […]

During the pandemic, in 2022 , half of the world’s population was wiped out. For those who survived, life had to go on. Life has to go on. After working so hard for your career and financial independence, quitting after the pandemic is not an option. The average nine-to-five workday went out with the plague. […]

For the first time in 41 years, THE DAWGS ARE NATIONAL CHAMPS!!! with a 33-18 victory over the Alabama Crimson Tide in the College Football Playoff National Championship In this interview with Head Coach Kirby Smart he stated “We knew we had something special after we beat Notre Dame and Auburn. We just kept getting […]

(Updating…) NEW: More document trouble for Novak Djokovic. On his Australian Travel Declaration, released by federal court yesterday, Djokovic stated he had NOT traveled in 14 days prior to his Jan 6 arrival here. In fact, Djokovic had traveled from Belgrade to Spain within that time. Novak Djokovic has reportedly been arrested following the decision […]

The email marketing channel is not dead. While social media has grabbed lots of attention, email revenue continues to rise. In fact, according to the DMA 2021 Consumer Email Trends Report, 83.25% of online consumers use email as their primary or secondary method for sharing their contact information with companies. That’s higher than any other […]

Apple became the first U.S. company to reach a $3 trillion market value on Thursday, surging past that milestone as its share price rose to a new high. Apple’s stock closed at $207.39, giving the company a market capitalization of about $3.005 trillion, based on its outstanding stock as of July 20. The company’s previous […]

Well, happy new year, the new beginning of your new life in 2022. After all the partying and celebrating, time for a new start. As you know we live in a very busy world and we tend to forget why we do the work we do. So here are few tips for Monday morning motivation: […]

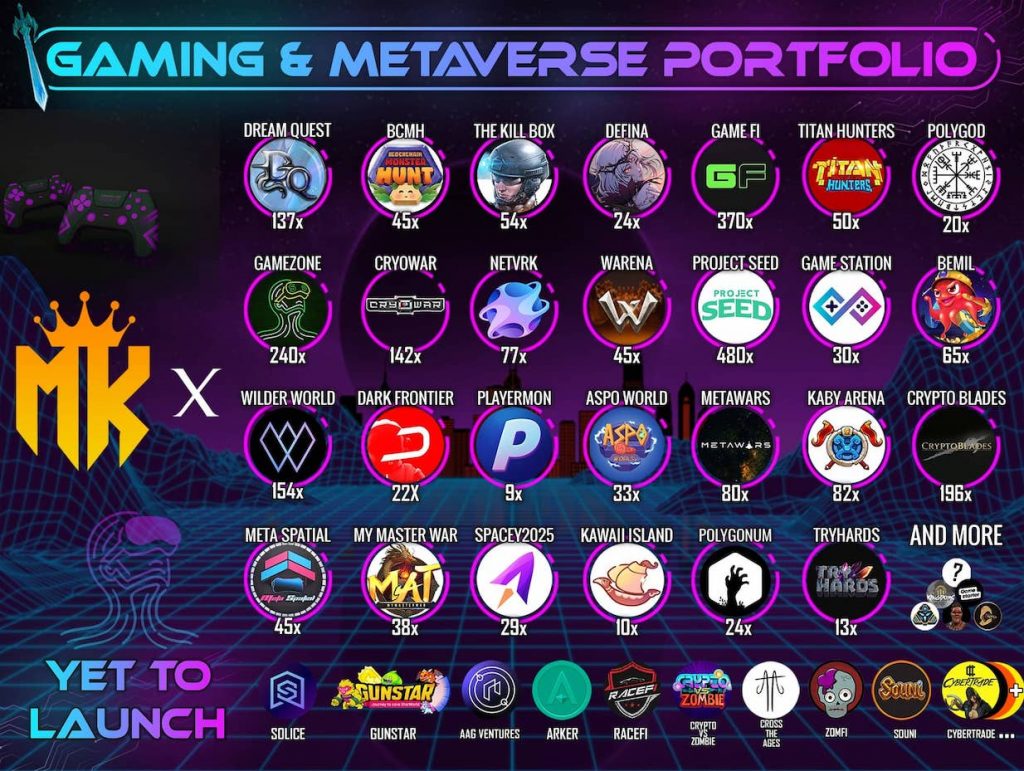

Cryptocurrency has been around for a while now, and many people are looking to find ways to earn it. One of the best ways to do this is by playing games. There are many different play to earn crypto games available, and each one offers its own unique benefits. Here is a list of top […]

Cyberattacks have made an impact on the U.S. food industry, which has led to shortages and disruptions in production and availability of certain products such as cheese slices and cream cheese. Appropriately enough, these disruptions seem to mirror the severity of the cyberattack; for example, Schreiber Foods, which was hacked weeks ago and is yet […]

Metaverse was launched in 2016 by Eric Gu (CEO & founder), former co-founder of NEO. Metaverse is a decentralized open platform of smart properties and digital identities , based on public blockchain technology. In this list of best metaverse crypto projects, we will show you best upcoming metaverse crypto projects for 100x. Top 25 best […]

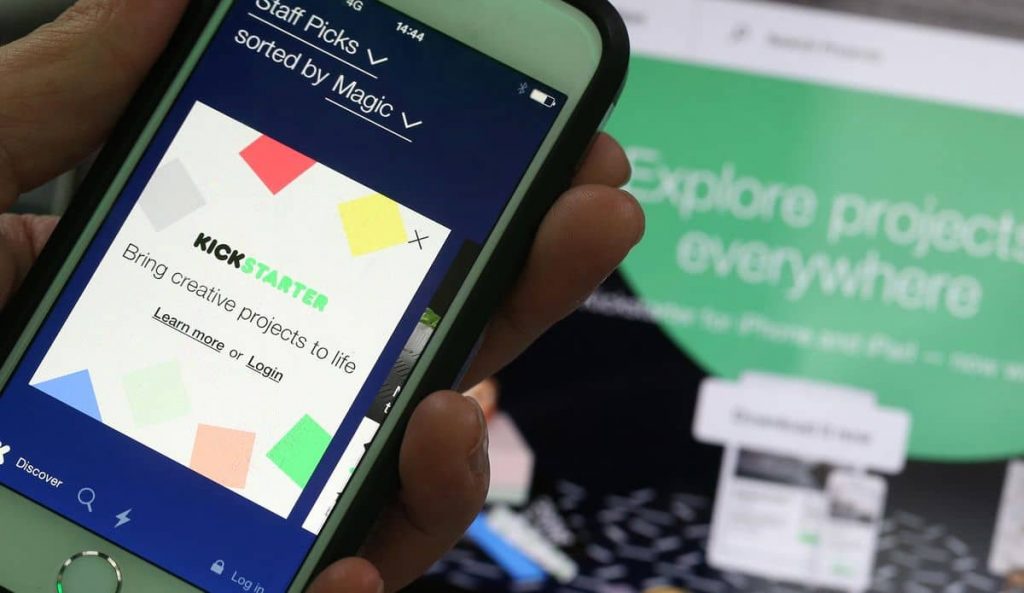

Kickstarter, one of the world’s most popular crowdfunding platforms, has announced that it will be moving its operations to a blockchain-based platform. The new platform, which is still in development, will allow users to pledge and donate tokens directly to project creators. These tokens will then be stored on a blockchain and can be used […]

Amazon Web Services reported a major outage on Tuesday, which caused outages on many popular websites and apps. The Amazon Web Services outage was first reported just before noon ET, and affected many websites and apps that rely on Amazon’s cloud platform for hosting. Amazon said the problem was with its S3 storage service, which […]

Apple released iPhone XS – and iPhone XS Max – in 2018 and both the models quickly became popular. But are they still available in the market? Apple’s widely popular iPhones, iPhone X and iPhone XR, were succeeded by iPhone XS and iPhone XS Max. Owing to its lower price and colorful chassis, the former model […]

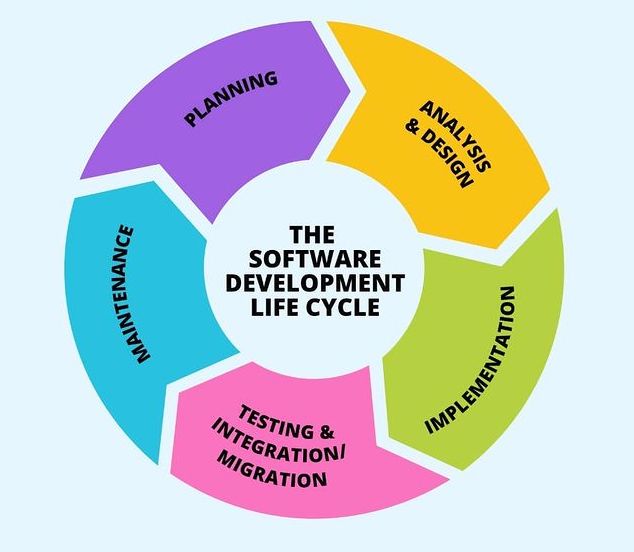

It is simply coined as SDLC. And this is a crucial process that will ensure high-quality software. As with products and inventions, the software also has to undergo a specific methodology to ensure its quality. And this life cycle consists of several stages. It begins with a thought and eventually translates into technical aspects. SDLC […]

If you want to invest more in your gaming setup, there’s no better way than to bulk it up with useful and unique gaming accessories. These nifty products can not only amp up your gaming experience, but it can also make your setup look more impressive. Check out my top recommendations. Iron Man MK45 MSI […]

After previously being considered a “niche” investment, cryptocurrency is now undoubtedly one of the most impressive financial disruptors across all sectors of society. In fact, as of February 2021, the number of active cryptocurrency traders was at 106 million globally. In the United States, 1 in 10 people invested in crypto in this year alone. Crypto even […]

The present era belongs to the subscription-based world where support services are now converted into a vital business element to gain most from the functioning. In such a scenario, the role of Salesforce Service Cloud is turning into a crucial one as it offers the most prominent personalized experience to the customers of any organization. […]